Prefabricated plastic formwork is one new material building formwork .According to T/CMRA-12-2021 production standard.It is one of the 10 technologies jointly recommended by 《China's Ministry of Housing and Urban-Rural Development》,It is also a important part 《the Prefabricated Building Evaluation Standard》,At the same time, it is also a new material product of green environmental protection, energy saving and carbon recycling.Prefabricated plastic formwork with rids is the innovative production tool that liberates productivity,it can completely replace the original building traditional template.In view of the waste of resources on the traditional template and subsequent waste pollution to the environment, our company to create customer-oriented environmental protection renewable assembly building template, the overall cost of construction enterprises can be greatly reduced, the quality can achieve better than the international effect.The product splicing time is short, the reuse efficiency is high, the labor intensity is low, the energy consumption is low and the environmental protection, thus reduces the building use cost, its emergence has realized the resource zero waste and the construction modernization, the standardization

Product detalles 1.Picture

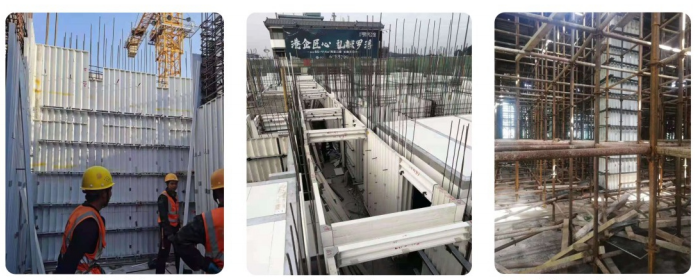

Product detalles 1.Picture Wall panel

inside corner template

inside corner template  Inside corner template

Inside corner template  1.Standard panel size

1.Standard panel size | Standard size | ||

| Panel size(mm) | Outer corner size(mm) | Innter corner size(mm) |

| 50×55 | 55×55 | 50×150 |

| 100×55 | 255×55 | 100×100 |

| 130×55 | 290×55 | |

| 150×55 | 310×55 | |

| 200×55 | ||

| 300×55 | ||

| 450×55 | ||

| 600×55 | ||

| Length can be customized length and buckle square connection, can be nailed or sawed, special-shaped parts can be combined with traditional formwork | ||

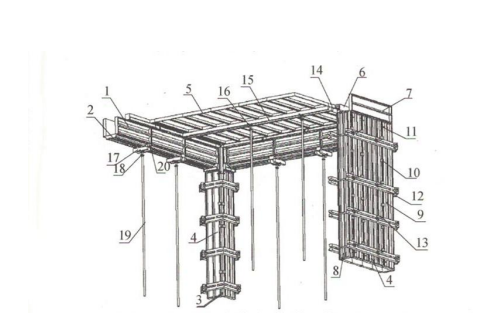

1.Beam side formwork 2.Beam bottom formwork 3.Outside corner template 4.wall and column formwork 5.Topside formwork 6.C -shaped channel 7.K Board 8.Wall terminal template 9.Angle of the template 10.U-shaped to check 11.locating the hook 12.reinforcement 13.washer and nut for tie rod 14.Early dismantling belt 15.beam 16.U- head 17.Beam bottom support 18.Adjuste screw rod 19.steel props 20.early dismantling head Product Characteristics 1. Good material properties: it is made of polymer composite material through high temperature extrusion processing to achieve the perfect combination of steel strength 2. Good mechanical properties: the arch design principle of Zhaozhou Bridge is adopted to cleverly achieve the best mechanical properties of the product structure. Reasonable modulus changes and the layout of ribs on the back and the advantage of extrusion can only reach the top of one plate 3. Good weather resistance: the product has good weather resistance -15℃-75 ℃ environment can be used normally 4. Low storage maintenance cost: strong product performance, no deformation, at the same time not afraid of wind, sun and rain, corrosion and other advantages for storage maintenance. 5. Recycling rate: can be recycled for more than 80 times, accessories can be used for more than 100 times 6. Strong versatility: The product has multi-module design, so that it can be used in different projects, and give full play to its value advantage when combined with wood mold 7. Not affected by the environment: not afraid of fire, not afraid of water, not afraid of tide, not afraid of sun, not afraid of electricity, corrosion and other advantages 8. No auxiliary installation equipment: no more than 18kg per flat, easy for workers to use, low labor intensity, no need for auxiliary equipment such as crane Demoulding reinforcement

1.Beam side formwork 2.Beam bottom formwork 3.Outside corner template 4.wall and column formwork 5.Topside formwork 6.C -shaped channel 7.K Board 8.Wall terminal template 9.Angle of the template 10.U-shaped to check 11.locating the hook 12.reinforcement 13.washer and nut for tie rod 14.Early dismantling belt 15.beam 16.U- head 17.Beam bottom support 18.Adjuste screw rod 19.steel props 20.early dismantling head Product Characteristics 1. Good material properties: it is made of polymer composite material through high temperature extrusion processing to achieve the perfect combination of steel strength 2. Good mechanical properties: the arch design principle of Zhaozhou Bridge is adopted to cleverly achieve the best mechanical properties of the product structure. Reasonable modulus changes and the layout of ribs on the back and the advantage of extrusion can only reach the top of one plate 3. Good weather resistance: the product has good weather resistance -15℃-75 ℃ environment can be used normally 4. Low storage maintenance cost: strong product performance, no deformation, at the same time not afraid of wind, sun and rain, corrosion and other advantages for storage maintenance. 5. Recycling rate: can be recycled for more than 80 times, accessories can be used for more than 100 times 6. Strong versatility: The product has multi-module design, so that it can be used in different projects, and give full play to its value advantage when combined with wood mold 7. Not affected by the environment: not afraid of fire, not afraid of water, not afraid of tide, not afraid of sun, not afraid of electricity, corrosion and other advantages 8. No auxiliary installation equipment: no more than 18kg per flat, easy for workers to use, low labor intensity, no need for auxiliary equipment such as crane Demoulding reinforcement  Inner corner outer corner and inner corner

Inner corner outer corner and inner corner  Wall reinforcement outer corner reinforcement outer corner reinforcement

Wall reinforcement outer corner reinforcement outer corner reinforcement  Demoulding effect Demoulding effect Demounlding effect Application

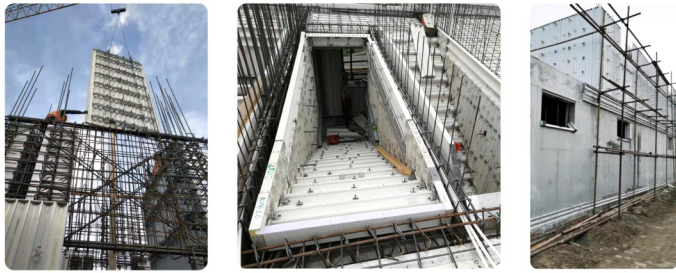

Demoulding effect Demoulding effect Demounlding effect Application  whole lifting Stairs assembled New countryside construction

whole lifting Stairs assembled New countryside construction  Pipe rack Drainage ditch Basement

Pipe rack Drainage ditch Basement  Wind-break wall Housing building Project site

Wind-break wall Housing building Project site  Our case

Our case