Introduction:

Aluminum formwork is getting more popular because of its light weight and good strength. It requires fewer supports and ties. Aluminum formwork system components include the walls, columns, beams, plates,templates and panel frames. Dedicated pin buckles are used to connect the templates.

The template system can be dismantled at an early stage. Standard specification size of the wall template is 100mm-450mm X 1800mm-2400mm.

Standard specification size of the roof template is 600mm X 600mm-1200mm with standard average weight of 23 kg/m

Specification

| Material | All aluminum formwork materials made of aluminum alloy |

| Lateral pressure | 30-40 KN/m2. |

| Weight | 25kg/m2. |

| Reused | more than 300 times |

Feature:

| Easy to work | It is about 23-25kg/m2, light weight means only a single worker could move the Aluminum Formwork easily. |

| Efficient | The Aluminum Formwork System is jointed by the pin, it is two times fast than wood formwork to install and dismantle, so it could save more work and work time. |

| Saving | The Aluminum Formwork System supports early-dismantling application, the construction working cycle is 4-5 days per floor, it is effective for cost saving in human resource and construction management.The Aluminum Formwork can be re-used more than 300 times, the economic cost is very low of every time using. |

| Safety | The Aluminum Formwork system adopts the integrative design, it could load 30-40KN/ m2, which could reduce the safety loophole leaded by the construction and materials. |

| High quality of construction. | The aluminum formwork is made by extrusion process, Legitimate design fine processing with very accurate measurements. The joints are tight, with a smooth concrete surface.No need heavy backing plaster, effectively for plaster cost saving. |

| Environment friendly | The aluminum material of the formwork could also be recovered after project finishing, it avoids the waste. |

| Clean | Different with the wood formwork, there is no wood panel,fragment and other waste in the construction area using the aluminum formwork. |

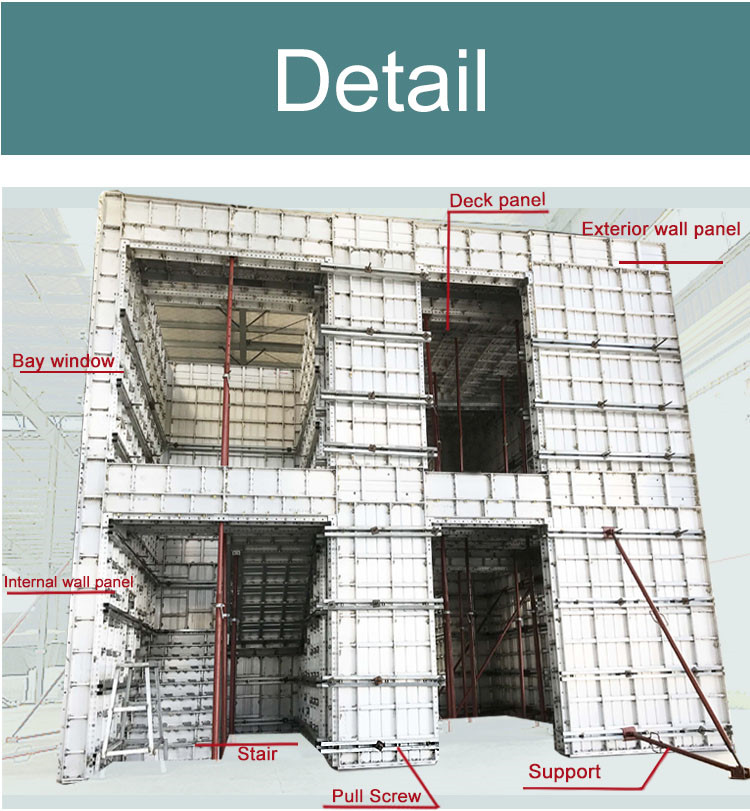

| Widely scope of application: | The Aluminum Formwork System is suited for application of walls, beams, floors, windows, columns, etc. |

Products detail

FAQ

Q1: What is Aluminum Formwork? Construction system used for forming all of the cast-in-place concrete structures of a building including walls, floors, beams, stairs etc. It can be easily applied to simple column, beam, and slab constructions and offers many advantages over other traditional construction methods. Q2:What kind of material is used in this panel? Aluminum alloy 6061 Q3:How do you use it? Panels are assembled using a very simple pin and wedge system to create a mold for concrete pouring. Walls are held together with high strength wall ties, while slab panels are supported by beams and props. After casting, the panels can be easily removed forreuse. Q4:Which port of loading Shanghai,Ningbo,Tianjing or Qingdao main port