1.Product Introduction:

Luowen new 63.5 Steel Frame Formwork System is mainly made up of steel frame,

plywood panel,scaffold bracket,coupler,compensation waler,tie rod,lifting hook , steel clamp and pull-push prop, etc.

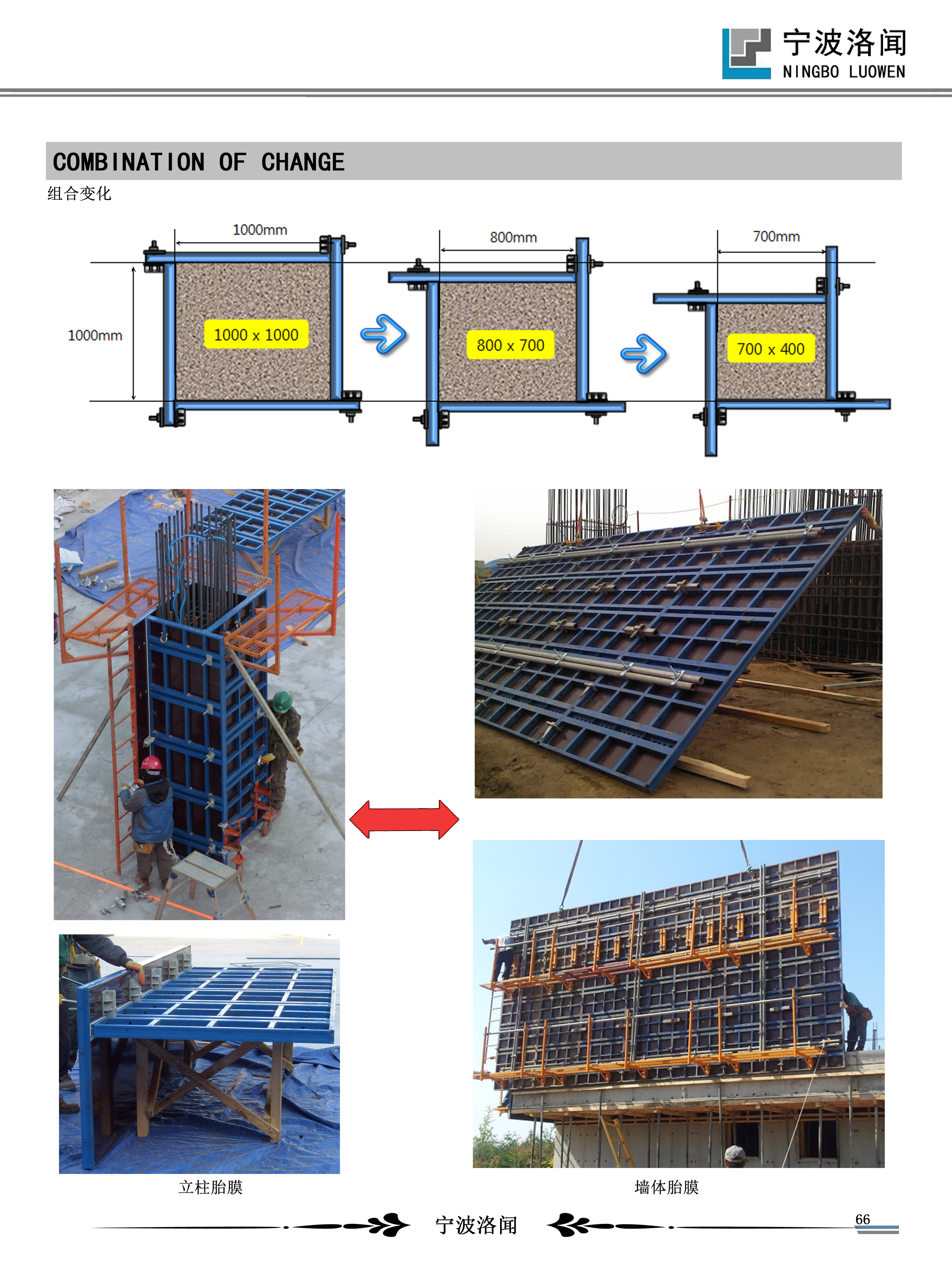

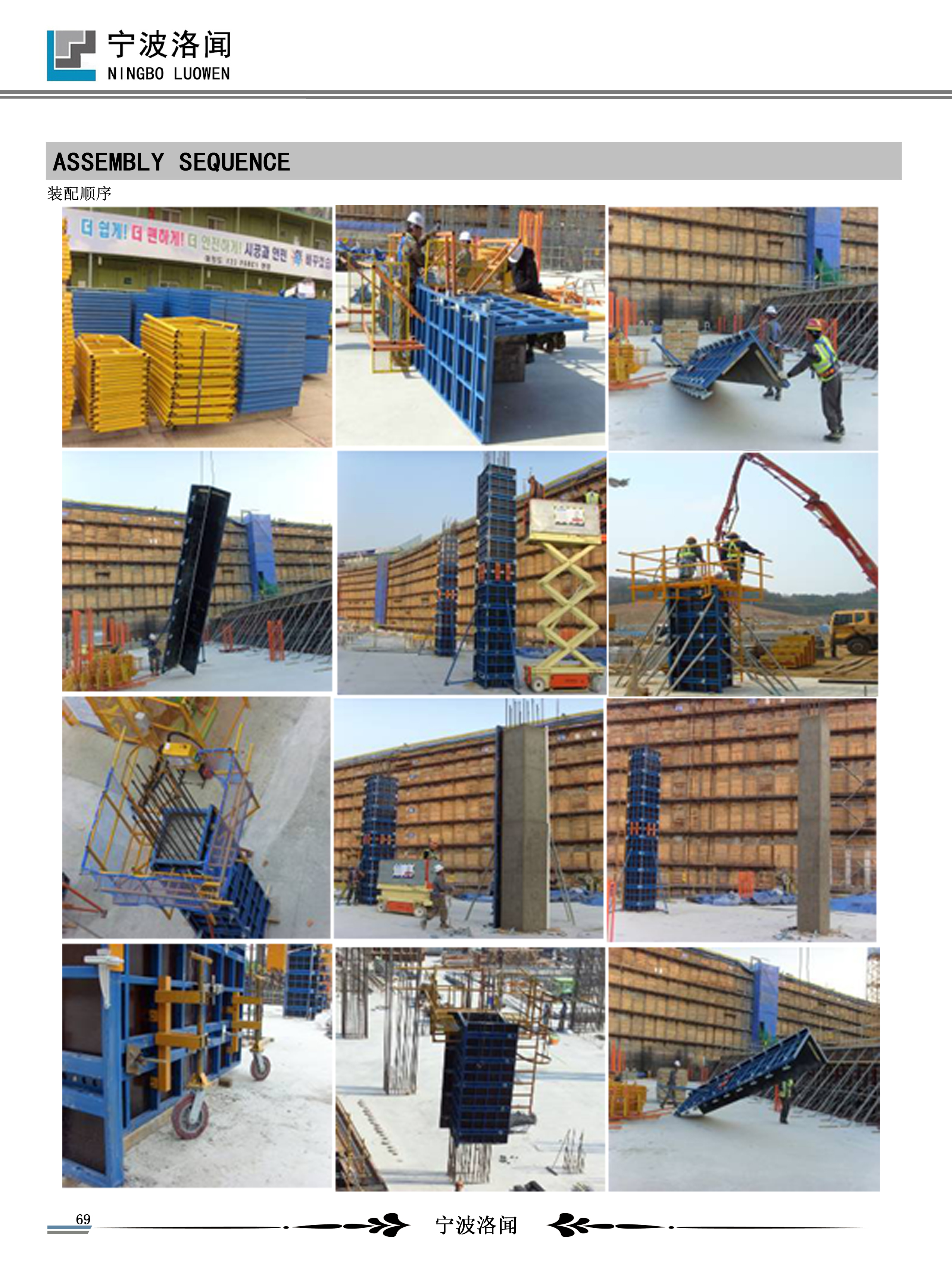

The column formwork can be assembled in advance on the ground or avoid complex construction sites. Use the equipment to place it on the construction site and pour the column concrete.

When the formwork is removed after the maintenance, it is not necessary to completely disassemble into a single piece, and the two pieces are separated into two groups, which are directly and easily used and erected to the next construction position, which is a system that can be directly used for assembly and re-use.

2.Product Details:

| 1.Frame thickness | 63.5mm |

| 2.Plywood thickness | 12mm |

| 3.Weight | 30kg/㎡ |

| 4.Lateral pressure | 60 KN/㎡ |

| 5.Surface treatment | paint spraying |

| 6.Reused | about 50 times |

| 7.Package | steel pallet |

3.Product Features:

1.The steel frame formwork is 12mm thickness plywood covered with hollow steel.

2.The frame is highly strengthened, and the wall formwork can bear lateral pressure

60KN/m2 while the column formwork can bear 80 KN/m2.

3.As a standardized system, it is flexible to assemble, wood batten can be filed to

satisfy the need of non-standard size.

4.The adjustable steel clamp is convenient to use ,and can hold tightly.

5.There is a prizing part designed in the corner ,which can help to position and

remove formwork easily.

6.The plywood is screwed on from the back when connecting frame and plywood ,

so the surface of the finished concrete is perfect.

7.The formwork series are a complete system with a full set of accessories ,and can

be set up flexibly according to project demand.

4.Packaging & Delivery:

1.package:steel pallet

2.delivery:20-30 days after order confirmed